Select your categories

Menu

Close

-

Categories

- Control box

- Magnetic sensors for “c” slot

- Programmable-analog magnetic sensors

- Magnetic sensors for “t” slot

- Magnetic sensors for dovetail slot

- Magnetic sensors for tie-rod cylinders

- No led magnetic sensors

- Special magnetic sensors

- Inductive sensors

- Ultrasonic sensors

- Optical sensors

- Accessories for magnetic sensors

- TECHNOLOGIES OVERVIEW

- DOWNLOAD

- Contact

- gimatic.com

- Register

-

Select your categories

- Back

-

Categories

- Back

- Rotary units

- Tool changer

- Profiles and brackets

- Grippers

- Linear actuators

- Vacuum

-

Nippers

- Back

- Air nippers

-

Sensors

- Back

- Control box

- Magnetic sensors for “c” slot

- Programmable-analog magnetic sensors

- Magnetic sensors for “t” slot

- Magnetic sensors for dovetail slot

- Magnetic sensors for tie-rod cylinders

- No led magnetic sensors

- Special magnetic sensors

- Inductive sensors

- Ultrasonic sensors

- Optical sensors

- Accessories for magnetic sensors

- Robot kit

- Options

- TECHNOLOGIES OVERVIEW

- DOWNLOAD

- Contact

- gimatic.com

- Register

Plastic Philosophy

End of Arm Tooling

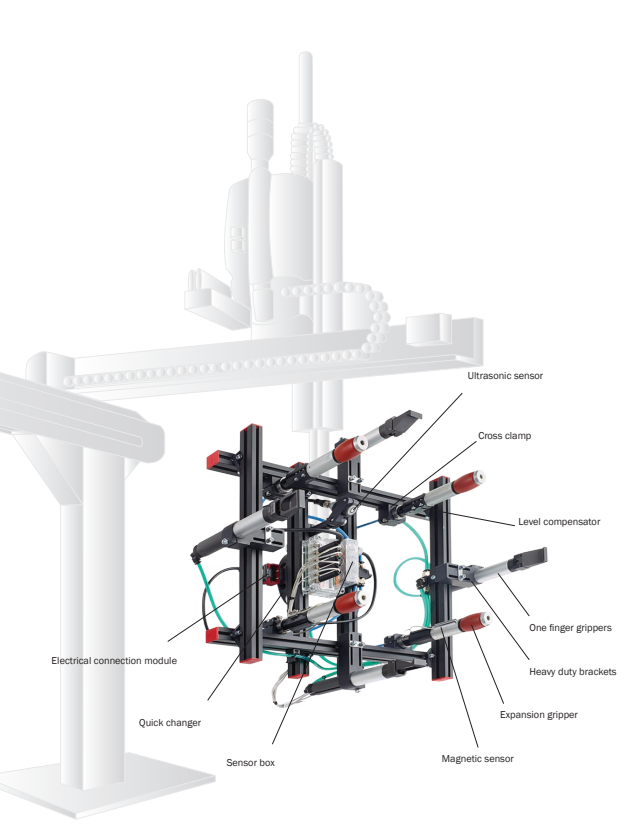

What is the EOAT?

It is the frame (with all necessary tools) mounted on the robot used to unload the injection moulding machine.

Its jobs are:

- to take the moulded part out of the mould;

- to gript it firmly;

- to seperate the moulded part from the sprue;

- to grip the sprue after cutting;

- to drop the sprue in the recycling machine;

- to unload the moulded part onto a pallet or a conveyor.

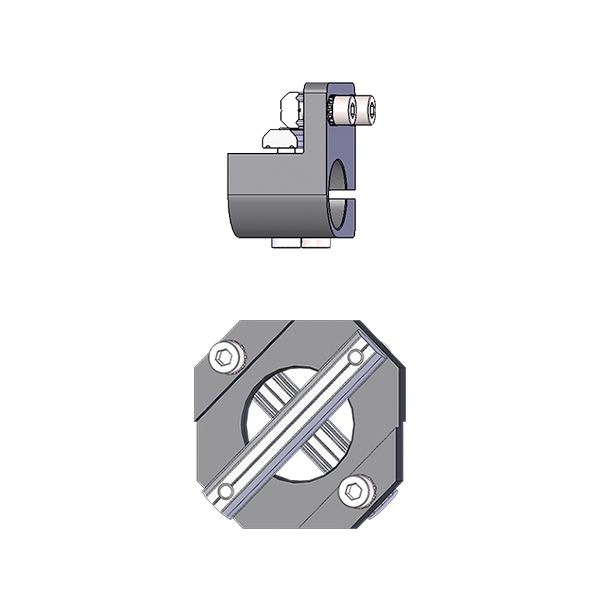

End of Arm

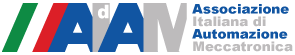

QC

- Quick changers for easy connections between the robot and the EOAT's.

- 15 models and 5 sizes up to 75kg payload.

- Pneumatic and electric connections.

- Air valves

- LOQC for the safety lock.

- RFID for the identification of the EOAT.

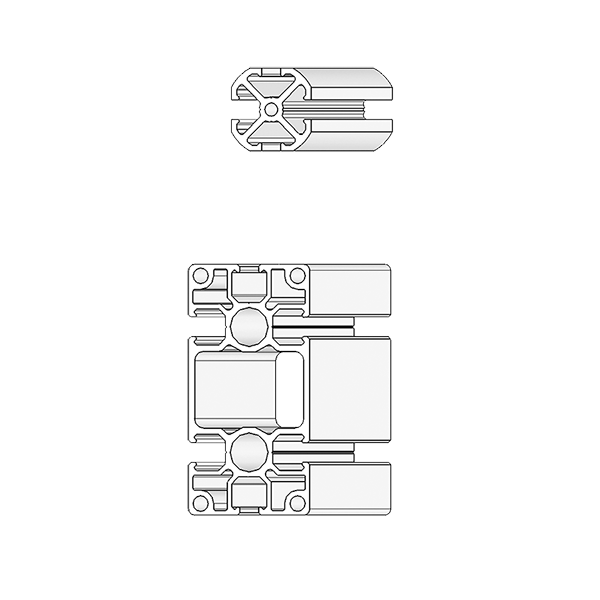

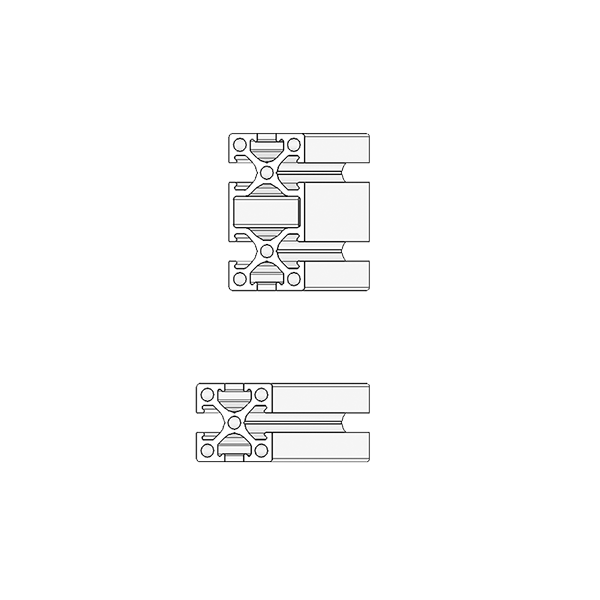

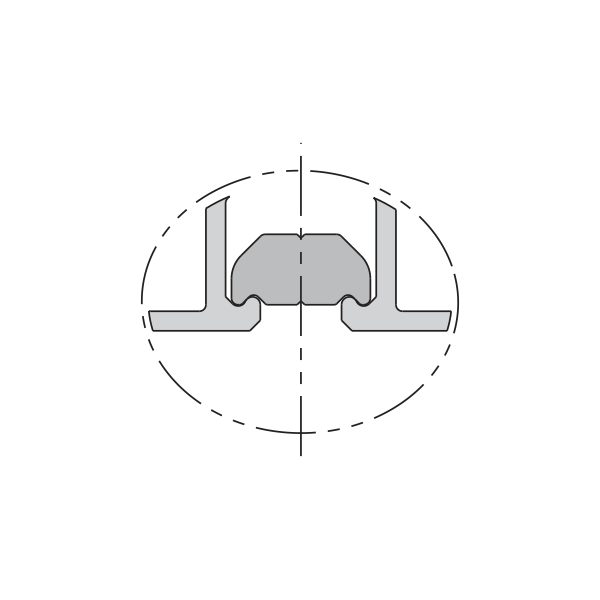

EMB

- Alluminum profiles for the EOAT framing.

- Special nut design for a rigid fastening.

- Black and silver anodization.

- Square or round shape.

- 15 sizes.

MFI

- Brackets for the actuator mounting on the frame.

- More than 500 codes for a perfect positioning.

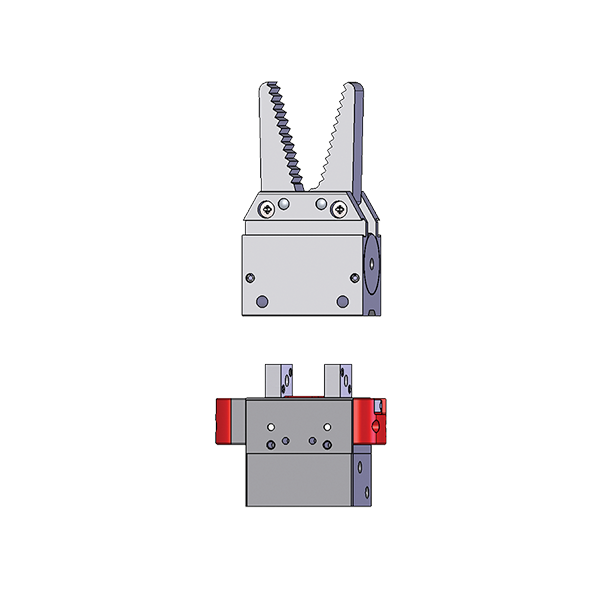

Tooling (EOAT)

Grippers

- One or two finger pneumatic grippers.

- Expansion gripper.

- For the part holding

- For the sprues holding

- For accurate insert positioning

- More than 200 codes EOAT dedicated.

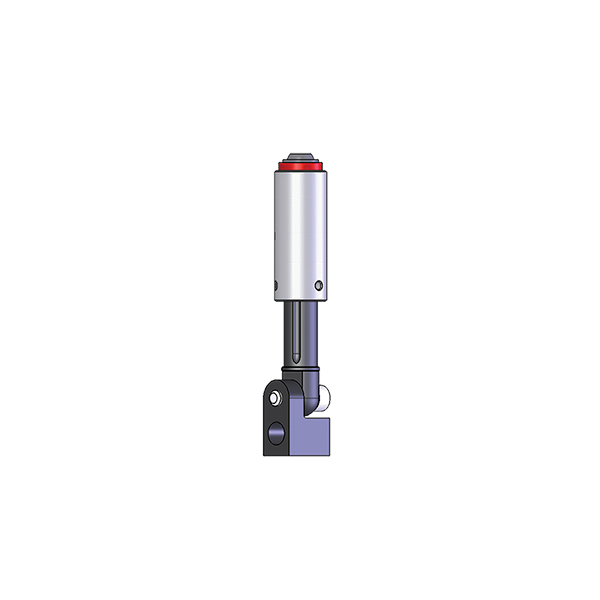

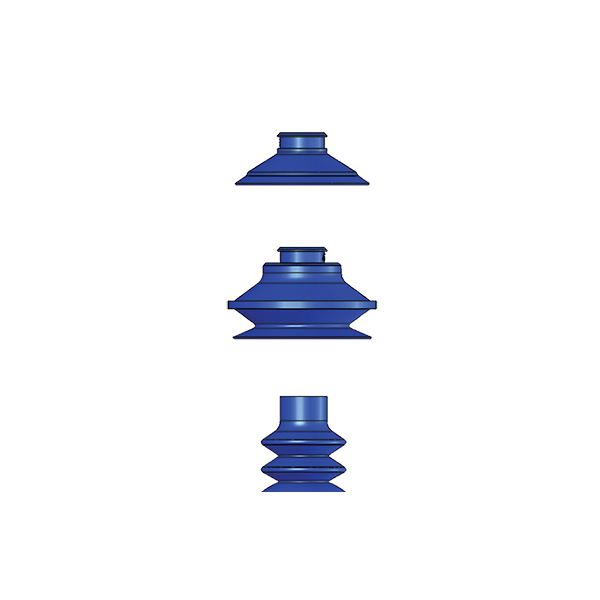

VS

- Vacuum cup holders.

- Suspensions with internal spring.

- Rotative or non-rotative.

- Non-marking rubber materials.

- More than 500 codes PLASTICS dedicated

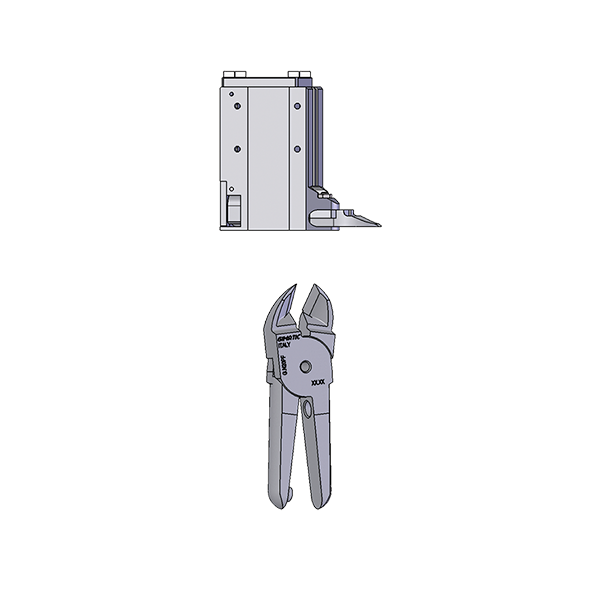

GN

- Nippers for degating.

- Scissor or guillotine style.

- 10 nipper sizes.

- Interchangeable blades.

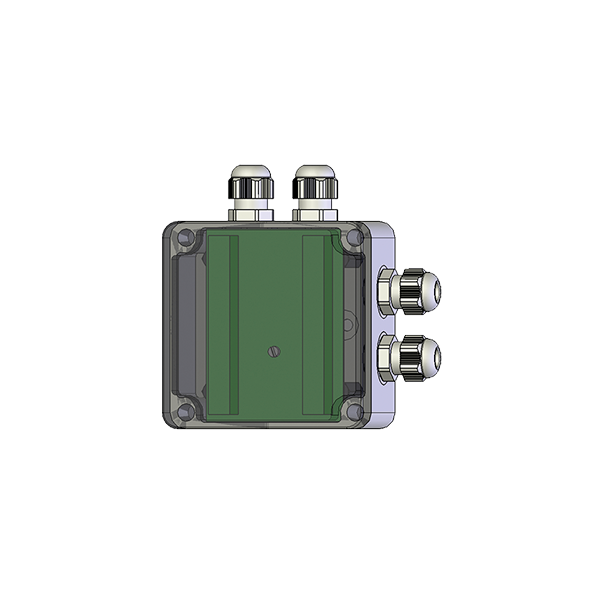

SB

- Sensor boxes for processing the signals from the actuators.

Newsletter

(Read documentation)

Wait...

Information

My account

Customer service

Gimatic S.r.l. -

VAT: IT02969010178 -

Via Enzo Ferrari n. 2/4, 25030 Roncadelle (Bs)

Powered by nopCommerce

Developed by Weblink

Copyright © 2026 Gimatic S.r.l. store. All rights reserved.

Newsletter

(Read documentation)

English

English